Foundation Engineering with Dynamic Pile Load Test Solutions

Table of Contents

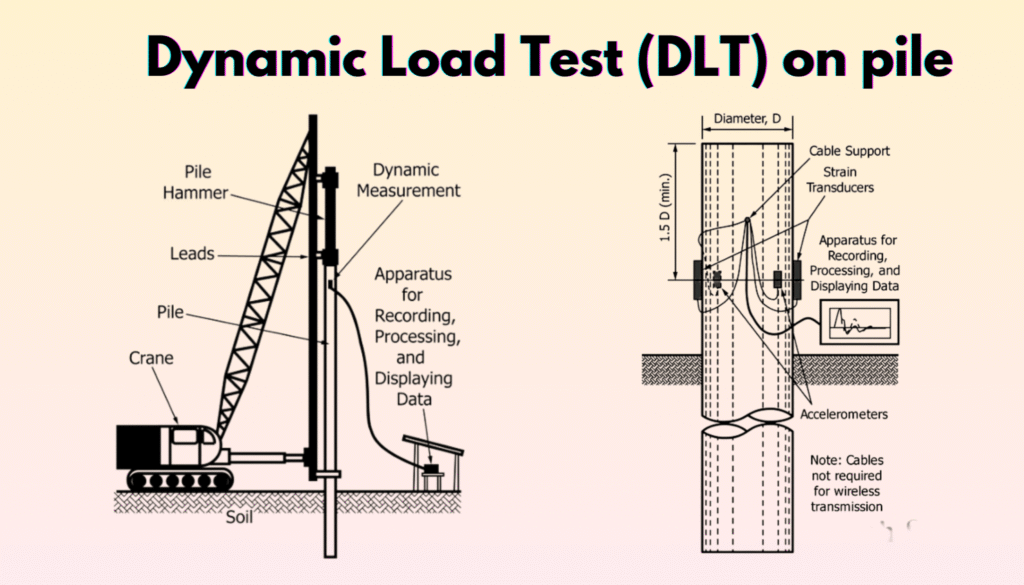

ToggleA Dynamic Pile Load Test (DPLT) is a quick and reliable method used to estimate the load-carrying capacity of driven piles.

It involves applying a force to the pile head, typically by dropping a heavy hammer or using a pile-driving rig, while specialized sensors measure the resulting stress and movement of the pile. This force mimics the impact conditions experienced during pile driving and allows engineers to calculate the pile’s axial load capacity through advanced wave equation analysis.

What Equipment Is Required to Carry Out a Dynamic Pile Load Test?

A Dynamic Pile Load Test requires several specialized instruments, including:

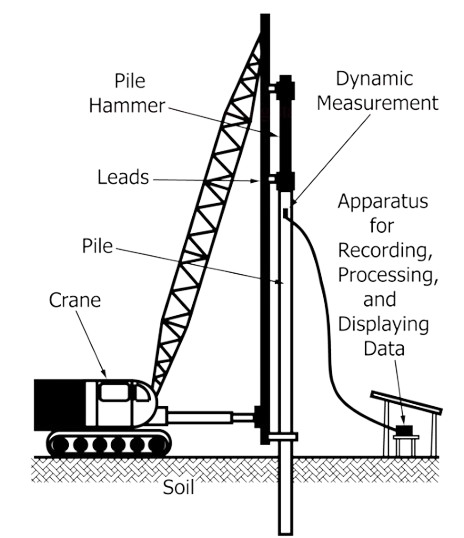

- Accelerometers: These measure the velocity of the pile head during impact.

- Strain Gauges: Attached to the pile, these measure strain to determine the force within the pile.

- Pile Driving Analyzer (PDA): A device that records and analyzes stress and velocity data in real-time.

- Drop Hammer or Hydraulic Hammer: Used to deliver an impact force to the pile head.

- Data Acquisition System and Software: For storing, analyzing, and interpreting results using wave equation analysis.

Forever Engineering Ltd. employs state-of-the-art equipment to conduct precise and safe testing, ensuring reliable data for decision-making.

Components of a Dynamic Pile Load Test

A Dynamic Pile Load Test consists of several critical components:

- Pile Under Test – Usually a driven pile, but occasionally cast-in-situ.

- Hammer System – Applies an axial force or impact load to the pile.

- Sensors – Strain gauges and accelerometers are attached near the pile head.

- Data Acquisition System – Collects time-dependent stress and motion signals.

- Analysis Software – Processes the data to estimate pile capacity, damping, and soil resistance.

Together, these components form a comprehensive system that provides accurate insights into the pile’s behavior under dynamic loading.

What are the Advantages of Performing a Dynamic Pile Load Test on Construction Sites?

Dynamic Pile Load Testing offers numerous benefits, including:

- ✅ Speed and Efficiency – A single test can be performed in under an hour, significantly speeding up construction timelines.

- ✅ Cost-Effectiveness – Less labor and equipment are required compared to static load tests.

- ✅ Mobility – The equipment is portable and can be used on remote or hard-to-access sites.

- ✅ Real-Time Results – Engineers receive immediate feedback, allowing for fast decision-making.

- ✅ Multiple Pile Testing – Enables testing of several piles in one day, improving quality control coverage.

- ✅ Reduced Setup – No need for heavy anchor piles or large reaction systems.

At Forever Engineering Ltd., we recommend Dynamic Pile Load Testing as a smart and modern choice for verifying pile performance, especially for projects requiring rapid execution and dependable data.

What is the Purpose of the Dynamic Pile Load Test?

The primary purpose of a Dynamic Pile Load Test is to:

- Determine the ultimate load capacity of the pile.

- Assess the structural integrity of the pile.

- Evaluate drivability and hammer performance.

- Estimate shaft and end-bearing resistance.

- Monitor pile performance during or after installation.

This method is especially useful for quality assurance, confirming that the installed piles meet design specifications.

How Does a Dynamic Pile Load Test Differ from a Static Pile Load Test?

While both tests aim to determine pile capacity, their methodologies and applications differ significantly:

| Aspect | Dynamic Pile Load Test | Static Pile Load Test |

| Testing Method | Uses a hammer to apply a dynamic load | Applies a slow, incremental static load |

| Equipment Required | Drop hammer, sensors, PDA system | Hydraulic jack, reaction frame, load cells |

| Duration | Fast – typically completed in a few hours | Slow – may take several hours to days |

| Cost | Generally more cost-effective | More expensive due to setup and duration |

| Mobility | Portable and easy to use on multiple piles | Less mobile, heavy setup required |

| Data Output | Estimates the pile capacity from wave equation analysis | Direct measurement of load vs. settlement |

| Best Use Case | Large-scale projects need quick testing of many piles | Detailed analysis for critical load-bearing piles |

Dynamic testing is faster, more economical, and can be repeated multiple times on multiple piles, making it ideal for large-scale projects. In contrast, static testing is more time-consuming and requires more space, but it provides direct load-settlement behavior, which is useful for final design validation.

Dynamic Pile Load Testing: Applications, Soil Effects, Testing Frequency, Safety, and Engineering Insights

Dynamic Pile Load Testing (DPLT) has become an essential tool in modern foundation engineering. It provides fast, accurate insights into pile capacity and soil behavior, enabling engineers to verify pile performance under load. At Forever Engineering Ltd., we utilize this advanced method to ensure the structural safety and reliability of our piling systems across a wide range of construction projects.

In Which Types of Projects Is a Dynamic Pile Load Test Most Commonly Used?

Dynamic Pile Load Testing is widely applied in various types of projects that involve deep foundations. It is particularly common in:

- High-rise buildings – where foundation loads are substantial and require precise capacity verification.

- Bridges and flyovers – which rely on pile-supported piers in varied soil conditions.

- Industrial plants and warehouses – especially those requiring rapid construction schedules and quality control.

- Marine and offshore structures – including jetties, port facilities, and oil platforms, where access is limited and static testing is difficult.

- Infrastructure projects – such as highways, railways, and airport terminals that need fast and repeated testing across multiple pile locations.

At Forever Engineering Ltd., we recommend DPLT in both urban and remote areas, thanks to its portability and rapid results, making it ideal for large-scale or fast-paced construction environments.

How Does Soil Type Affect the Results of a Dynamic Pile Load Test?

Soil characteristics play a critical role in the interpretation of dynamic load test results. The test measures stress wave responses, which are influenced by:

- Soil density and stiffness – In dense, cohesive soils like clay or compact sand, resistance is higher, potentially leading to greater pile capacity readings.

- Soil damping – Softer soils absorb energy more quickly, which may cause underestimation of pile resistance if not properly accounted for in the analysis.

- Layered soil profiles – Variation in soil layers can affect wave propagation, requiring detailed modeling to ensure accurate interpretation.

How Often Should Dynamic Pile Load Tests Be Conducted During Pile Installation?

The frequency of Dynamic Pile Load Testing depends on project size, pile type, and the importance of the structure. General recommendations include:

- Initial Testing – Before full-scale installation, test a few piles to confirm the design assumptions.

- Periodic Quality Control – Conduct regular tests during installation to monitor consistency and detect any anomalies in driving resistance or pile integrity.

- Post-driving Testing – Perform tests immediately after installation or after a waiting period to assess long-term soil resistance (especially in clay, where setup effects occur).

Typically, testing 1–2% of total piles is considered good practice for large projects, although more may be tested if conditions are variable or if performance concerns arise.

Forever Engineering Ltd. customizes testing frequency based on client needs, geotechnical findings, and structural requirements to maintain optimal quality assurance.

What Safety Precautions Are Necessary During a Dynamic Pile Load Test?

Safety is paramount during any construction activity, especially when dynamic forces are involved. Essential precautions include:

- Securing the test area – Only authorized personnel should be present during testing.

- Proper PPE – All workers must wear helmets, gloves, safety shoes, and high-visibility clothing.

- Inspection of equipment – All sensors, cables, and the impact system must be checked for defects or loose connections.

- Coordination and communication – Clear roles and signaling between the hammer operator, test team, and engineers are critical.

- Fall and debris protection – Ensure all tools and instruments are secured and the pile top is clear of loose materials.

At Forever Engineering Ltd., our team follows strict safety protocols and undergoes rigorous training to ensure that every test is conducted with maximum protection for both people and equipment.

How Do Engineers Use Dynamic Pile Load Test Results to Ensure Foundation Integrity?

Dynamic Pile Load Testing generates valuable data on pile performance, including:

- Ultimate bearing capacity

- Pile integrity and potential defects

- End-bearing vs. skin friction distribution

- Soil-pile interaction behavior

Engineers analyze this data using wave equation-based software to model real-world behavior. The findings are then compared with design expectations. If discrepancies occur, engineers may adjust pile lengths, redesign foundations, or modify installation methods.

By using DPLT results, Forever Engineering Ltd. ensures that every foundation is both structurally sound and economically optimized, helping clients avoid costly failures or overdesign.

Conclusion: Dynamic Pile Load Test

The Dynamic Pile Load Test (DPLT) is a modern, efficient, and highly reliable method for evaluating the performance and capacity of foundation piles. It offers engineers and contractors rapid insights into load-bearing behavior, structural integrity, and soil interaction, all with minimal disruption to the construction process.

Compared to traditional static testing, DPLT provides faster results, is more cost-effective, and is ideal for testing multiple piles across various types of projects, ranging from high-rise buildings and bridges to marine structures and industrial facilities.

At Forever Engineering Ltd., we consider dynamic pile load testing a vital tool in ensuring safety, optimizing designs, and maintaining the highest quality standards in foundation engineering. By combining advanced equipment, experienced professionals, and strict safety protocols, we deliver precise results that our clients can trust.

Whether you’re building vertically, spanning long distances, or working in complex soil conditions, the Dynamic Pile Load Test is the smart choice for securing your foundation with confidence.