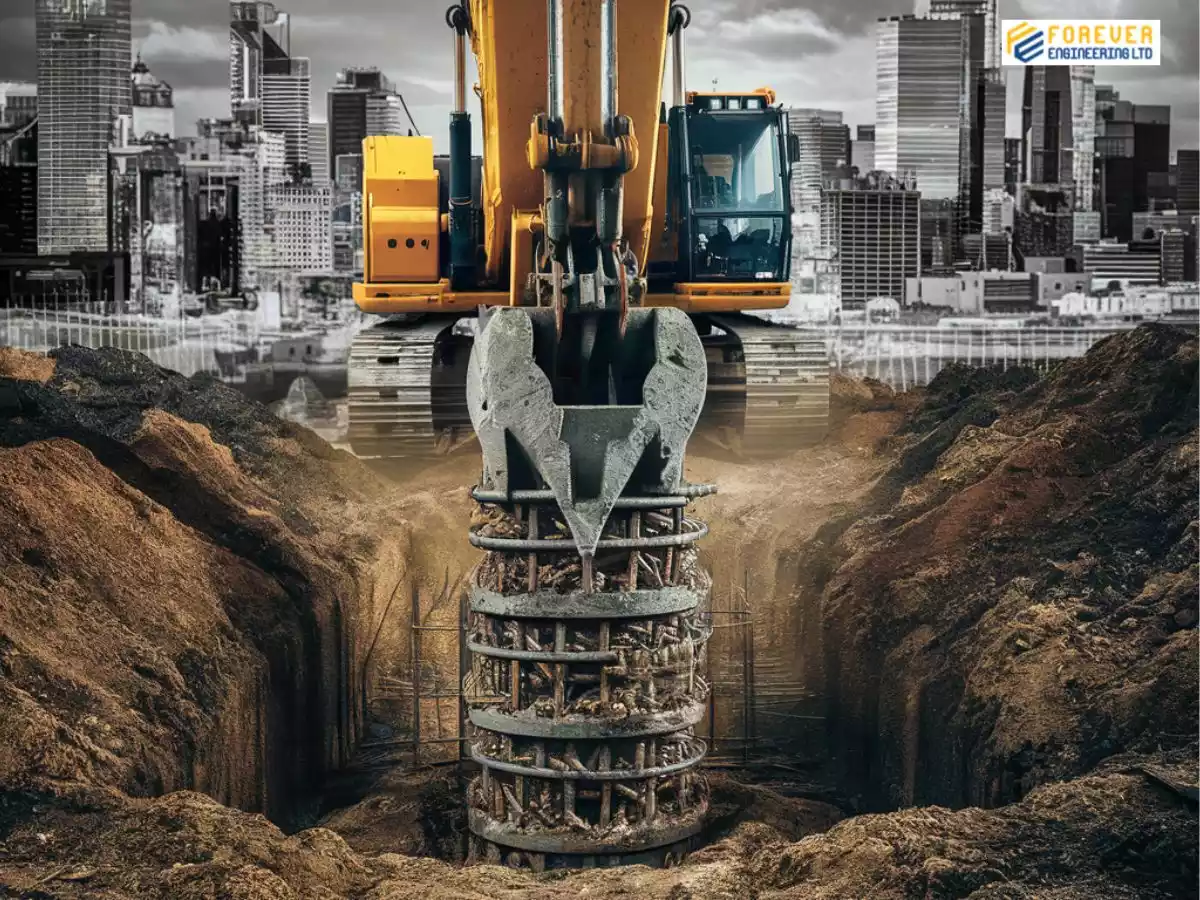

Expert Bored Cast in Situ Piles Services

In the world of construction, the foundation is everything. It secures the durability and stability of structures, both grand and vital—from majestic high-rises to extensive bridges. That’s where Forever Engineering Ltd comes into play. Specializing in bored cast in situ piles, we don’t just lay the groundwork; we ensure your projects stand on a foundation designed to meet the unique challenges of your site. Our commitment to quality, efficiency, and sustainability means we’re not just building foundations— we’re building the future.

Create Rock-Solid Foundations with Strong Base

Whether it is an industrial complex, bridge, or flyover, we offer the best bored cast in situ piles services to create a stable foundation capable of supporting heavy loads and withstanding lateral forces. If the ground condition of your preferred location is good, Forever Engineering Ltd can help you build a favorable foundation solution.

Our team of experts can provide cost-effective pile construction solutions at optimal value without any foundation failure or structural instability. Our experienced professionals will identify cost-saving opportunities through value engineering.

Get The Service You Deserve From Our Team of Experts

When it comes to bored casting in situ piles, it involves soil analysis, structural design, construction management, and safety compliance. We have a diverse team of professionals, including civil engineers, geotechnical engineers, structural engineers, project managers, piling contractors, and quality control engineers.

Our civil engineers will design and supervise the construction of bored cast in situ piles, while geotechnical engineers will assess soil conditions and analyze ground properties. We have structural engineers who can ensure the integrity and stability of bored cast in situ piles to meet project requirements and safety standards.

Core Features of Our Bored Cast in Situ Piles Services

In-depth Knowledge of Local Conditions

Our professionals are well-trained in understanding the specific soil types and geological conditions in the service area. This helps them create efficient project planning and customized solutions.

High-quality Materials

We use top-grade materials for concrete to ensure reliable support for structures and minimize the risk of foundation failures. Our experts also use high-quality reinforcement cages to withstand heavy loads and external forces.

Quality Control Measures

We follow established procedures for concrete mix design and quality control testing. Our professionals will also scrutinize protocols to choose the correct pile shaft diameter, depth, and verticality. We don't use any destructive testing methods to assess pile integrity.

Efficient Construction Capabilities

We have highly qualified, skilled crews. They can efficiently operate drilling rigs, place concrete, and finish piles. Our experts can also handle steel reinforcement cage fabrication and installation when needed.

Best Bored Cast in Situ Piles Service Provider

Every construction project has some core needs. We handle every bored cast in situ pile construction project cautiously. Our experienced team, advanced techniques & equipment, and sustainability practices made us the best choice for driven and bored cast in situ piles. Our professionals use efficient drilling techniques and optimize material usage to keep the project cost as low as possible.

At Forever Engineering Ltd, we pride ourselves on meeting and exceeding industry standards with every project we take on. Our methodical approach begins long before the first drill touches the ground.

We engage in thorough planning and analysis, ensuring that every step of the bored cast in situ pile process is tailored to your project’s specific requirements. This attention to detail is not just about adhering to technical specifications; it’s about understanding the vision behind your project and its impact on the community it serves.

Our Bored Cast in Situ Pile Construction Methodology

By choosing us, you’re entrusting your project to a team that views your success as our own. Our commitment to excellence is reflected in our meticulous preparation, which lays the groundwork for a smooth, efficient, and successful construction process. Let us bring our expertise, dedication, and passion for engineering to your project, and together, we will create a foundation that stands the test of time.

Here is how we will execute our bored casting situ piles.

Step: 01) Our experts will plan the construction project and make ready the machines and equipment

Step: 02) Then, they will set up the Bentonite pumping system to stabilize the hole during bored pile creation. A driller and electric generator are also necessary.

Step: 03) Next, our professionals will place the borehole and augur into the ground. It will ensure the correct depth and load-bearing soil.

Step: 04) Afterward, they insert a steel casing to prevent the borehole walls from caving in and easily remove groundwater and soil.

Step: 05) Based on the project requirements, our professional team will use either a hydraulic rotary pile drilling machine or a Bangla rotary pile drilling machine.

Step: 06) They will constantly pump Bentonite fluid into the hole to carry away soil cuttings and minimize water inflow for cleaner concrete work.

Step: 07) Our team members will clean up all loose soil and debris to prevent any weak spot creation and ensure a solid concrete bond with the soil.

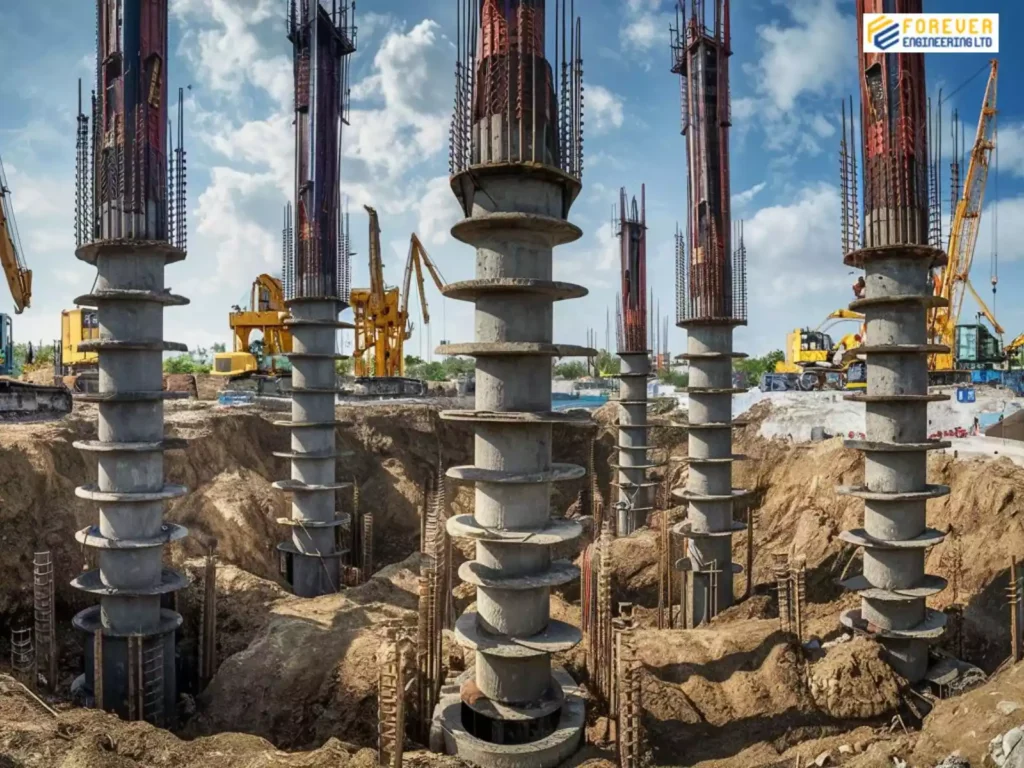

Step: 08) Next, we will gradually insert a reinforcement steel cage into the borehole for increased tensile strength and improved load-bearing capacity.

Step: 09) Afterward, our professionals insert a Tremie pipe to ensure controlled and high-quality concrete placement.

Step: 10) Finally, they will withdraw the temporary steel casing once the concrete is poured appropriately and has reached a specific point.

Our Machines & Equipment

We use advanced tools and machinery during bored casting in situ piles to maintain consistent quality, install faster, and cope with different soil conditions.

Based on the soil conditions, our engineers generally use two types of drilling machines. They will conduct a site investigation to assess the soil type and select the most appropriate option.

Hydraulic Rotary Pile Drilling Machine

Our professionals use hydraulic rotary drilling rigs, especially for challenging soil conditions like highly muddy ones. The rig generates only a tiny form of mud or slurry during the drilling process. They follow a wet drilling method with bentonite slurry to wash away the excavated soil cuttings and support borehole walls. We mainly use this advanced machine due to its precise drilling capabilities and enhanced safety features.

Bangla Rotary Pile Drilling Machine

We will use our Bangla rotary machine for cohesive and dense sandy soils, such as clay and silty clay, well-compacted sandy soils with low acceptable content, etc. This enables us to save the overall construction cost. However, it may be dusty in some cases. This aspect is particularly important in urban or sensitive project sites where environmental and health safety standards are stringent.

Our Work Gallery

We have been in the piles construction industry for more than a decade. Our dedicated employees improve themselves through intensive training and continuous learning. They will give consistent attention to detail in every aspect of work to ensure work quality and reliability. See how we brought ideas to life. Explore our project gallery.

Why Choose Us?

When you choose Forever Engineering Ltd. for your bored cast in situ piles services, you’re not just selecting a service provider; you’re partnering with a team that genuinely cares about the foundation and longevity of your project. Our unique blend of technical prowess, attention to detail, and dedication to excellence sets us apart.

We understand that the success of our client’s projects is paramount, and our holistic approach towards project management, from meticulous planning to the final execution, ensures we meet your specific needs with precision. Our commitment to ongoing innovation, coupled with our unwavering focus on sustainability and safety, makes us the ideal choice for clients who demand the highest standards.

Advanced Equipment

We have a good collection of advanced equipment to improve drilling precision and concrete pouring. It will enhance the construction's overall efficiency, accuracy, and safety.

Commitment to Safety

Forever Engineering Ltd provides comprehensive safety training to all their personnel involved in pile construction to promote a safe working environment and mitigate risks effectively.

Quality Assurance

Our employees follow a rigorous quality assurance procedure during Bored Cast in situ pile construction. They test the soil and review pile designs and construction plans to avoid all possible imperfections.

Sustainable Practices

Our employees always follow environmentally friendly construction practices, such as minimizing waste and noise pollution, Reusing or recycling leftover items, disposing of waste responsibly, etc.

Proven Track Record

We have successfully completed more than hundreds of situ piling projects. This showcases our service capability and quality of work.

Your Best Partner for Bored Cast in Situ Pile Services

As one of the best bored cast site pile service providers in the construction industry, we aim to provide our clients with reliable, efficient, and sustainable foundation solutions.

Our skilled workforce includes well-trained drillers, operators, and inspectors to ensure efficient drilling and quality control. It helps us to avoid costly mistakes and guarantees strong foundations. Plus, we have a massive collection of modern machinery to complete the construction project in a timely while minimizing risks and errors.

24/7 Emergency Container House Supply

+880 1894 615871, +880 1894 615872

We Offer Free Consultations

Submit Your Questions To Get An Expert Opinion

Frequently Asked Questions (FAQ's)

Bored casting is used in situ pile construction where the soil has a lower load-bearing capacity. High-quality concrete with reinforcement cages is added to create high structural loads.

Different machines and equipment are used for bored casting in situ pile construction, such as hydraulic rotary drilling rigs, drilling heads and attachments, A Tremie pipe, a concrete pump, and a bentonite slurry system.

Sinkhole formation is one of the significant risks associated with bored piling. It mainly occurs from inadequate ground support and uncontrolled water flow.

Engineers mainly use an overhead reaction system, which involves considering the reactions (forces) transferred from the pile upwards to the upper structure.

Driven piles are typically used in softer soils, whereas bored piles are preferred in denser or more challenging soil conditions to minimize disturbance.

Forever Engineering Ltd stands at the forefront of providing innovative, reliable, and sustainable bored cast in situ pile services. With our vast experience, advanced equipment, and a commitment to safety and quality, we ensure that each project we undertake is built on a solid foundation, literally and metaphorically.

Our approach combines the expertise of our diverse team of professionals, advanced drilling techniques, and a deep understanding of local conditions to offer tailored solutions that meet and exceed our clients’ expectations. From the initial soil analysis to the final concrete pour, we are dedicated to achieving excellence in every phase of the construction process.

Our proven track record and commitment to sustainability and safety underscore our position as a trusted partner in the construction industry. Choose Forever Engineering Ltd for your next project, and let us lay the groundwork for a successful and durable structure that stands the test of time.