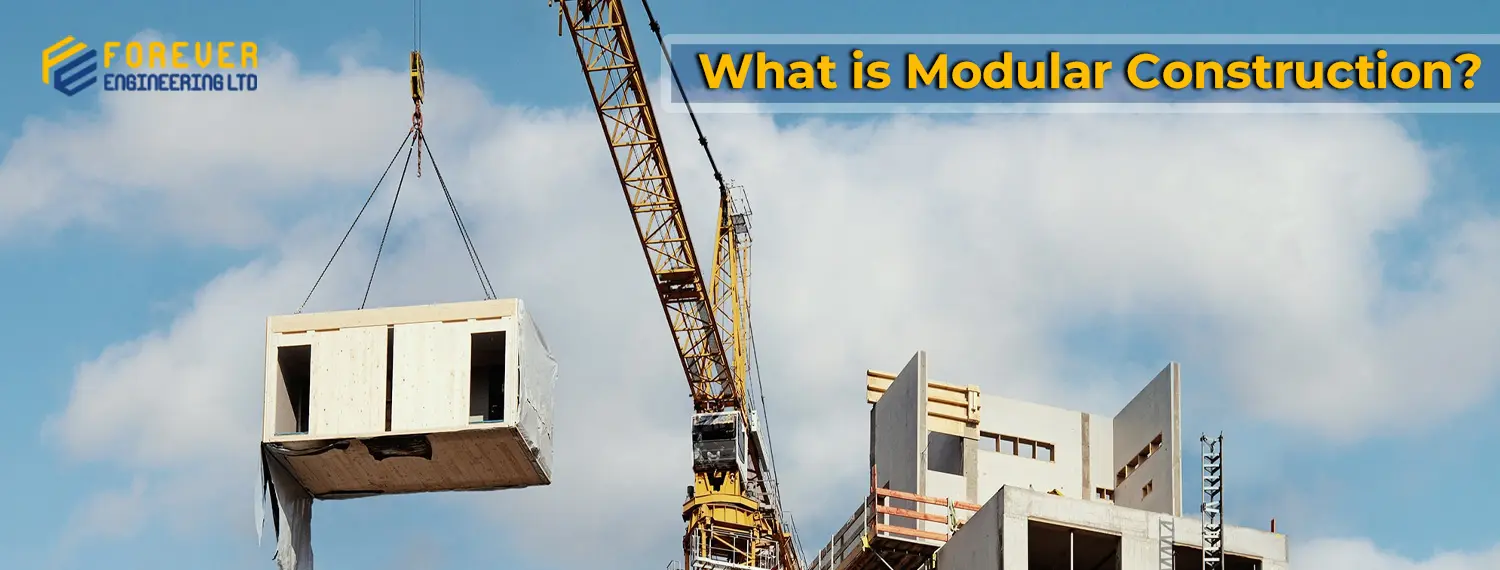

In the real estate sector, there is a clear tendency toward expanding construction outside of the construction site. One way is modular building. Forever Engineering has been involved in numerous modular construction projects around Bangladesh.

The use of modular construction is marketed as a way to solve the lack of qualified workers, lower waste on the working site, and battle rising interest rates and building costs through increased efficiency. Some engineers and architects, however, are reluctant to use this strategy because they want their designs to be protected and because they believe it has the functionality and flexibility to handle particular project typologies. Where therefore is the truth located? Continue reading to get an overview of What is Modular Construction, its applications, benefits and more.

When was Modular Construction Invented?

Table of Contents

ToggleThe earliest known example of modular building dates back to the 1830s, when John Manning, a carpenter in London, built his son a prefabricated house. This house was constructed in sections and then transported from England to Australia for final assembly.

This building technique gained popularity with the development of prefabricated buildings during World War Two and for the quick reconstruction of homes after the war’s conclusion. It was also widely used during the California Gold Rush of the 1840s in the United States when it was utilized to build the “Crystal Palace” for Britain’s Great Exhibition of 1851. The Modular Building Institute was established as a result of the widespread use of modular construction in the United States.

What is Modular Construction

Modular construction is a style of architectural design in which each room or space is constructed independently. It can also refer to the actual construction process, which is based on prefabricated modules. In other words, each of the following—walls, floors, ceilings, doors, windows, etc.—is built separately.

This modular construction method is perfect for compact places like townhouses, offices, apartments, dorm rooms, retail stores, and identical classrooms. Large spaces like factories, warehouses, and offices can also benefit from it. Therefore, without any confusion you can create modular office construction.

When conventional building techniques are impractical due to space constraints, modular construction is frequently employed. For instance, it might be necessary to enlarge a factory, but the current layout prevents this. Or perhaps a warehouse needs to grow, but buying the necessary land might be too costly.

Advantages of Modular Construction

Let’s start with the many advantages and benefits of modular construction.

1. Saves Time

One obvious example is modular construction, which allows a portion of the work to be done in a factory while site work and foundations are completed on-site. This time-saving advantage expedites construction while maintaining efficiency, keeping the project on schedule. A modular strategy has the ability to reduce the entire timetable by 30 to 60 percent.

2. No Possibility of Weather Delay

Furthermore, concerns about weather postponing the modular units’ assembly are essentially avoided because the modules are manufactured inside a controlled environment. Additionally, it gives employees safer and more comfortable working environments, which increases productivity and yields higher-quality products. Additionally, the modules typically come on-site pre-configured with appliances, countertops, flooring, plumbing, and electrical fittings, saving minimal effort and time to get up and running.

3. No Need to Store Materials

Material storage is another benefit of modular construction. It’s challenging to stage and move objects around on a site with little space, particularly in a small urban area like Philadelphia. This leads to disarray, hinders productivity, and raises the risk of theft. Building sites can stay safer, and cleaner, and offer greater room for workers to move about freely when the modules are constructed in a factory.

4. Lower Labor Costs

One significant, and perhaps debatable, benefit is labor economics. As previously noted, modular technology enables highly sought-after skilled personnel to stay in fixed places under-regulated, and safer settings. Modular facilities can be positioned to draw in these highly competitive laborers and benefit from crucial access to raw materials and logistical hubs, such highways and rail lines, which are typical in other sectors of the economy, like the automobile and technology sectors. Although labor savings can vary greatly, building cost savings of up to 25 percent are possible.

5. Lower Volume of Waste

A new UK study claims that modular construction can reduce materials by up to 90%. In order to reduce waste on each project, modular solutions are gaining popularity as environmental concerns in the building sector continue to develop. Even in the plants that assemble the building components, recycling is being maximized.

6. Cost Savings

For a variety of reasons, modular building frequently results in cost reductions. A well-managed manufacturing setting lowers labor costs and boosts output while buying components in bulk can save prices. Faster occupancy and lower finance costs are further advantages of the accelerated construction schedule, which are especially helpful for commercial projects.

Types of Modular Construction

A modular construction system is often made up of many FRP (fiber-reinforced plastic) composite panels that are joined together to produce a membrane structure with complete structural integrity.

In accordance with construction requirements such as the International Construction Code (IBC), a modular manufacturer offers a broad selection of residential, commercial, and industrial modular units in a range of floor plan configurations.

Here are the 2 main types of modular construction buildings:

1. Permanent Modular Construction (PMC)

Permanent modular construction (PMC) is a prefabrication method for single or multistory buildings that uses offsite, lean manufacturing processes to create deliverable modules. In contrast to projects that solely use site-built construction, integrating PMC modules into site-built projects or as a stand-alone turnkey solution offers better quality control and lowers waste.

Moreover, permanent modular structures are perfect for mixed-use situations. A hybrid facility can be created by combining a PMC structure with a pre-engineered steel building or a concrete tilt wall.

2. Relocatable Building (RB)

A Relocatable Building (RB) is constructed in sections or in its entirety via a modular construction approach, which allows it to be transported to various building sites and reused.

An RB satisfies the demand for a temporary area and conforms with state rules, local construction code requirements, and installation specifications provided by the manufacturer. Furthermore, an RB is a fantastic choice for emergency and natural disaster assistance services because of its adaptability.

An RB works effectively with full MEP (Mechanical, Electrical, and Plumbing), fixtures, and finishes when a quick, temporary space solution is required. For use as offices, medical facilities, sales centers, restrooms, schools, etc., movable modular buildings are perfect.

Relocatable buildings offer a variety of benefits, including:

- Ease of relocation

- Fast delivery

- Greater flexibility

- Low-cost reconfiguration

- Accelerated depreciation schedules

Applications of Modular Construction

1. Residential Buildings

In the residential sector, modular construction is frequently utilized for single-family homes, apartment buildings, and multi-family housing. Different housing demands and tastes can be accommodated by a multitude of styles and layouts made possible by the capacity to customize modules.

2. Commercial Buildings

Modular construction is utilized in the commercial sector for retail establishments, hotels, and office buildings. In this industry, speedy building is especially beneficial because it enables enterprises to open sooner and turn a profit faster.

3. Healthcare Facilities

For healthcare institutions like hospitals and clinics, modular construction is perfect. Modular construction’s factory-controlled atmosphere is ideal for healthcare buildings since it requires accuracy and quality control. Additionally, when it comes to quickly updating or expanding healthcare infrastructure, construction speed can be quite important.

4. Educational Institutions

An increasing number of colleges and universities are using modular buildings to swiftly and effectively meet their need for new facilities. To accommodate expanding student populations, modular classrooms, dorms, and administration facilities can be quickly erected.

The Challenges of Modular Construction

Although modular construction has many advantages, it also has several drawbacks, including:

Complicated Approval Process

Additional inspections for local and state building codes may be necessary for modular building approval. The project timeframe could be negatively impacted by the convoluted approval process.

Design Updates

Modifications to a traditional build’s design can be made while the structure is being built, but after pre-assembled modules are taken out of a modular manufacturing plant, it becomes more difficult.

Permit Issues

States have different procedures for granting permissions. State-level permissions for module interiors, for instance, might not be approved in other places.

Reduced Resell Value

There is still a negative perception of modular construction’s quality. The belief that a modular property’s quality is equal to or higher than that of a traditionally built property will not shift quickly.

Site and Size Constraints

Transporting modules in vehicles with different capacities and sizes is challenging, even though modules are typically limited to a set maximum size. Furthermore, while rectangular-shaped modules are typical in modular construction, an unevenly shaped building site could present design difficulties.

The Future of Modular Home Construction

In the upcoming years, the modular building sector is anticipated to see growth in popularity. This kind of building has many benefits that make it the ideal choice in a number of scenarios. The modular building will transform construction in the coming years because of its rapid and efficient construction.

Future modular construction trends include a greater emphasis on sustainability and green building techniques as well as the creation of new technology that will facilitate quicker, simpler, and more accurate modular construction. Prefabricated designs and solutions are expected to remain popular, especially for large-scale projects and commercial structures. Furthermore, modular construction will draw more and more attention as an economical substitute for traditional construction methods as their costs grow.

All things considered, it is evident that modular building is here to stay and will only get bigger as more people become aware of its numerous advantages.

Forever Engineering Role in Modular Construction

As a pioneer in modular building, Forever Engineering offers creative and effective building solutions. Custom design, cutting-edge engineering, and superior prefabrication in a regulated factory setting that guarantees accuracy and consistency are all included in our extensive offerings. We are excellent at managing projects; we coordinate every facet of the building to cut costs and schedules. Our methods are centered around sustainability, making use of energy-efficient designs and environmentally friendly materials.

We provide adaptable and superior modular structures to a range of industries, including residential, business, healthcare, and education. Our collaborative approach is driven by our dedication to client satisfaction, guaranteeing precise communication and customized solutions all the way through the project’s lifetime. For a dependable, eco-friendly, and effective modular building partner, go with Forever Engineering.

Conclusion

Right now, you have learned what is modular buildings. Numerous modular construction techniques and materials are used in modular construction, and each is appropriate for a particular project type and set of requirements.

construction provides creative, customizable solutions for a variety of building types, including volumetric or panelized modules, steel, wood, and concrete structures as well as movable or permanent buildings. Stakeholders can maximize the advantages of this effective and adaptable building method by making educated judgments by having a thorough awareness of the various forms of modular construction.

Frequently Asked Questions

Can modular buildings be customized to meet specific design requirements?

Yes, modular buildings can be highly customized to meet a wide range of design and functional requirements. While modular construction involves some standardization for efficiency, it also allows for significant flexibility in design. Modules can be tailored to specific architectural styles, layouts, and functionalities, making them suitable for diverse applications such as residential homes, commercial spaces, healthcare facilities, and educational institutions.

How does modular construction differ from traditional construction?

Modular construction differs from traditional construction primarily in its approach to building. In modular construction, modules are built in a controlled factory environment while site preparation occurs simultaneously. This parallel process reduces overall construction time. Additionally, the factory setting allows for more precise construction and quality control, resulting in high-quality buildings with less waste and environmental impact.

Can modular construction be used for different types of buildings?

Absolutely. Modular construction is highly versatile and can be used for a wide range of building types, including residential homes, apartment complexes, office buildings, hotels, schools, and healthcare facilities. The ability to customize modules allows for a variety of designs and layouts, catering to different needs and applications.